Air/Fuel Ratio

Air / Fuel Ratio

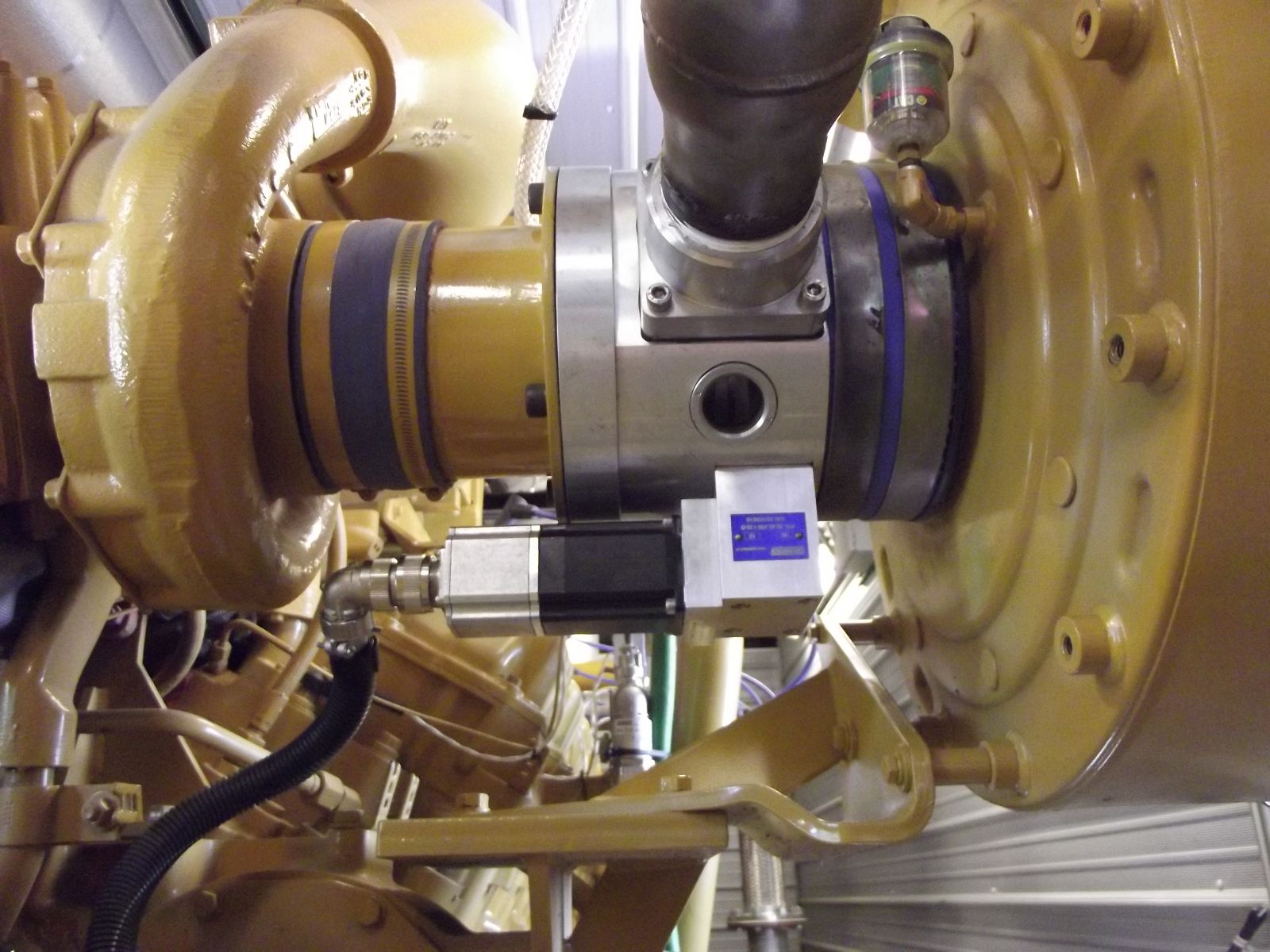

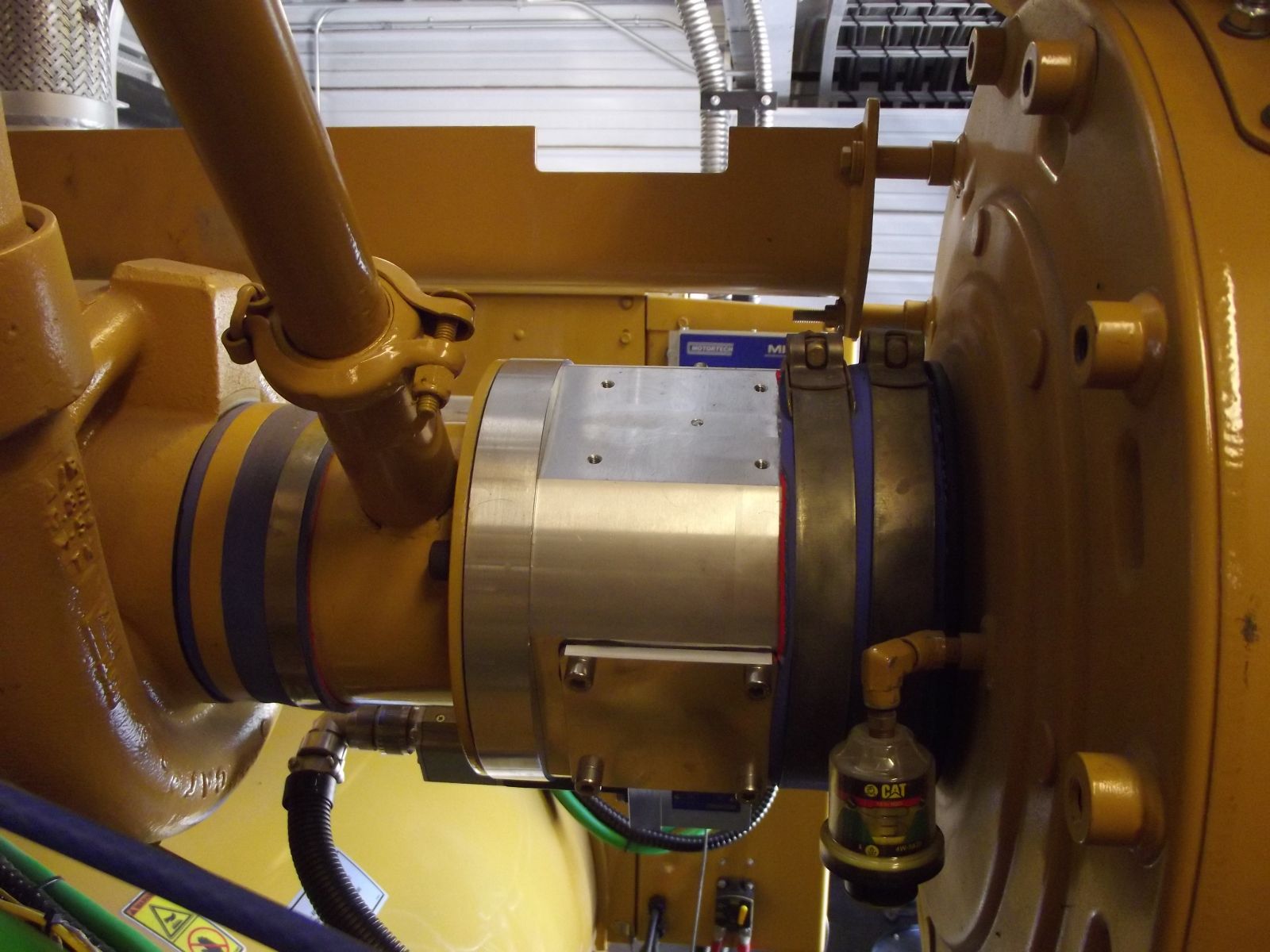

The main task of the gas mixer is to mix the fuel (gas) and air so that the gas engine achieves optimal combustion. Here, the decisive optimization parameters are a high degree of efficiency and low emissions that comply with relevant regulations. In the VariFuel2, gas and air are mixed based on the Venturi effect. Based on the suction vacuum of the engine, the air is sucked through the air inlet into the Venturi nozzle. The Venturi effect generates an underpressure at the narrowest point, which causes the gas to be sucked in through the gas inlet. This way gas and air are mixed and released at the Venturi outlet.Based on different design sizes and different flow bodies in the Venturi nozzle, it is possible to achieve various volume flows.

Regulation of the Air/ Fuel Mixture

The fuel (gas) is drawn into the nozzle via the adjustable openings 2 in a fuel ring. The openings of the fuel ring are adjusted using a drive belt either manually or, normally, via a stepper motor, depending on the VariFuel2 type. The stepper motor can be controlled using a stepper motor card (VariStep) which can process the signals of a master control. In addition, the VariFuel2 gas mixers are equipped with a port for an air pressure gauge and a connection for the pulse line of a zero pressure regulator.