Solenoid Valve

NORMALLY-OPEN MANUAL RESET SOLENOID VALVES TYPE M16/RMO N.A. EEX - M16/RMOC N.A. EEX - M16/RM N.A. EEX

DESCRIPTION

The fonctioning principle of M16/RM N.A. EEX is very simple and extremely safe. The coil, when under tension, releases and springs up the closing device. The reset is manual to check the causes for gas detection. During normal conditons there is no electric absorption, no wear and tear.The versions M16/RMOC N.A. EEX can be equipped with a button that allows to close manually the gas substituting the manual tap of the gas line allowing also to test at intervals the good working of the solenoid valve.

In conformity with:

97/23/EC PED Directive

(6 bar versions)

2014/34/EU ATEX Directive

(ex 94/9/EC)

2014/30/EU EMC Directive

(ex 2004/108/EC)

2014/35/EU LVD Directive

(ex 2006/95/EC)

TECHNICAL DATA

• Use: not aggressive gases of the 3 families (dry gases)

• Threaded connections Rp (brass body): (DN 15 ÷ DN 25) according to EN 10226

• Threaded connections Rp: (DN 20 ÷ DN 50) according to EN 10226

• Flanged connections PN 16:(DN 65 ÷ DN 350) according to ISO 7005

• On request ANSI 150 flanged connections

• Power supply voltage: 12 Vdc, 12 V/50 Hz, 24 Vdc, 24 V/50 Hz, 110 V/50-60 Hz, 230 V/50-60 Hz

• Power supply voltage tolerance: -15% ... +10%

• Max. working pressure: 500 mbar or 6 bar

• Environment temperature: -15 ÷ +50 °C

• Protection degree:IP65

• Class:A

• Group:2

• Closing time: <1 s

• Coils: poliammidic resin encapsulated with glass fibre, connection type DIN 43650; the insulation class is F (155°) and the enamelled

copper wire class is H (180°).

MATERIALS

• Die-cast aluminium (UNI EN 1706)

• OT-58 brass (UNI EN 12164)

• 11S aluminium (UNI 9002-5)

• galvanized and 430 F stainless steel (UNI EN 10088)

• NBR rubber (UNI 7702)

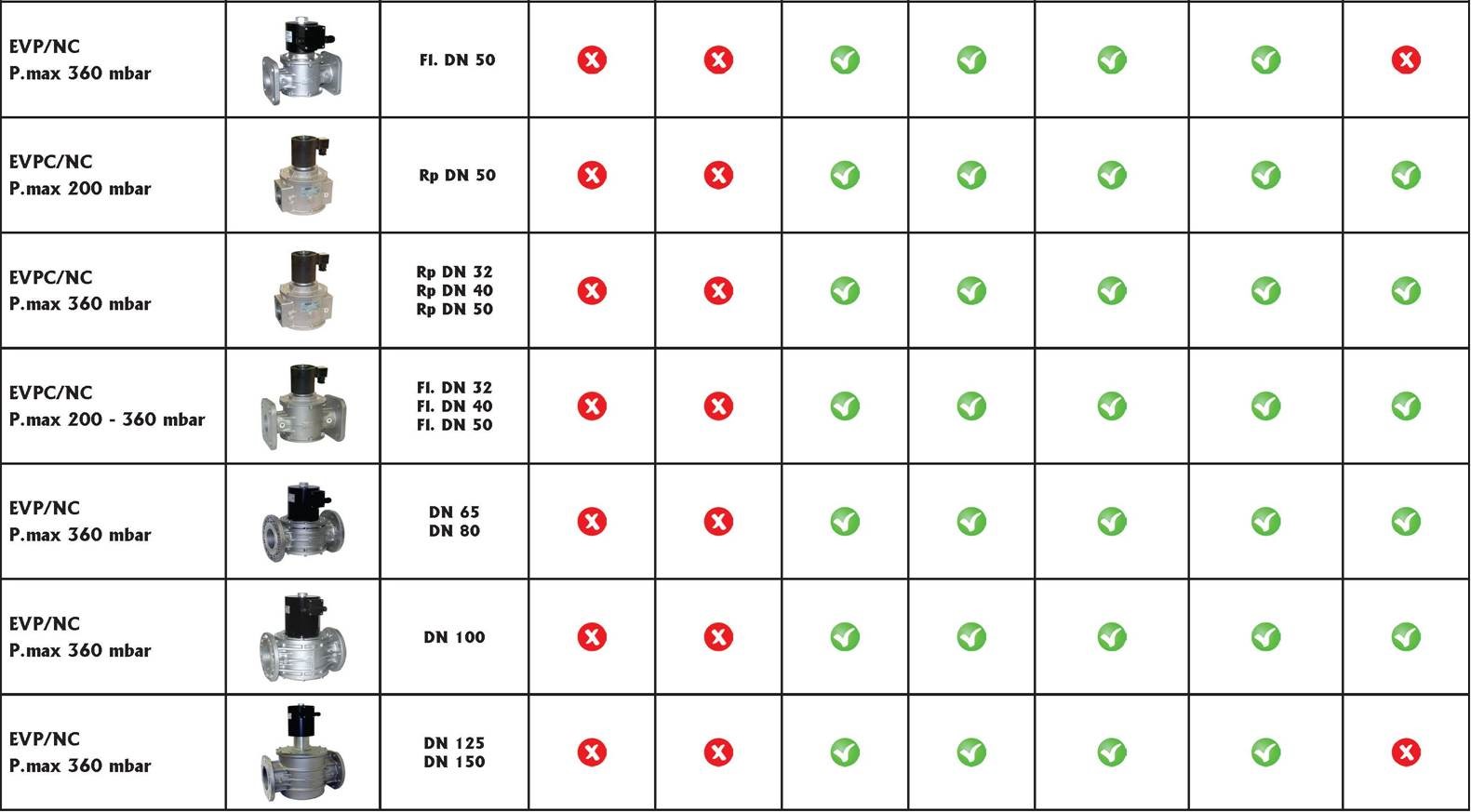

EVP/NC - EVPC/NC AUTOMATIC NORMALLY CLOSED SOLENOID VALVES

DESCRIPTION

Gas interception automatic normally closed solenoid valves that open when the coil is powered and close when there is no tension. These solenoid valves can be controlled by pressure switch, thermostat, etc.

They can be equipped with a flow regulator (models EVPF/NC - EVPCF/NC). The solenoid valve can be supplied also with the closed position indicator switch (CPI Switch). Reference standard EN 161

In conformity with:

2009/142/EC Gas Directive

2014/34/EU ATEX Directive (ex 94/9/EC)

2014/30/EU EMC Directive (ex 2004/108/EC)

2014/35/EU LVD Directive (ex 2006/95/EC)

COILS:

EVP DN 15 - 20 - 25, EVPC DN 25 - 32 - 40 - 50: poliammidic resin encapsulated with glass fibre, connection type DIN 43650; the insulation class is F (155°) and the enamelled copper wire class is H (180°).

EVP DN 32 - 40 - 50 - 65 - 80 - 100 -125 - 150: the insulation class and the enamelled copper wire class is H (180°).

SIL LEVEL

Level of SIL of solenoid valve stand-alone is SIL 2, when are installed two solenoid valves in series

level reached is SIL 3, like indicated on standard EN 676:2008. The solenoid valve has level PL d.

TECHNICAL DATA

• Use: not aggressive gases of the 3 families (dry gases) On request biogas versions available too (only on aluminum bodies)

• Threaded connections Rp:DN 15 - DN 20 - DN 25 - DN 32 - DN 40 - DN 50 according to EN 10226

• Flanged connections PN 16:DN 25 - DN 32 - DN 40 - DN 50 DN 65 - DN 80 - DN 100 - DN 125 - DN 150 according to ISO 7005

• Threaded connections NPT or flanged ANSI on request

• Power supply voltage (see table)

• Max. working pressure: 200 o 360 mbar

• Power supply voltage tolerance: -15% ... +10%

• Power absorption: see coils and connectors table

• Cycles/hour: see coils and connectors table

• Power absorption: see coils and connectors table

• Environment temperature: -20 ÷ +60 °C

• Max superficial temperature: 85 °C

• Protection degree: IP65

• Class:A

• Group:2

• Closing time:<1 s

• Opening time:<1 s

MATERIALS

• Die-cast aluminium (UNI EN 1706)

• OT-58 brass (UNI EN 12164)

• 11S aluminium (UNI 9002-5)

• galvanized and 430 F stainless steel (UNI EN 10088)

• AVP stainless steel (UNI EN 10087)

• NBR rubber (UNI 7702)

• FKM rubber (UNI 9542)

• nylon 30% glass fibre (UNI EN ISO 11667)

• metal net filter on DN 15 ÷ DN 50

• viledon filter on DN 65 ÷ DN 150

NORMALLY-CLOSED MANUAL RESET SOLENOID VALVES TYPE M16/RMO N.C. - M16/RM N.C.

DESCRIPTION

This solenoid valve is made to guarantee the gas interception either for gas detector signals (methane, lpg, carbon monoxide and so on) and safety thermostats, or for an electric black out. In order to be more reliable this solenoid valve can be reset only when electrically supplied and only if the gas detector doesn’t send any danger signal.

Simply powering the coil does not open the valve. The reset mechanism has to be operated by hand.

EC certified according to EN 161 According to the 2009/142/EC Directive (Gas Directive) 6 bar versions According to the 97/23/

EC Directive (PED Directive) According to the 94/9/EC Directive (ATEX Directive) According to the 2004/108/EC Directive

(Electromagnetic Compatibility) According to the 2006/95/EC Directive

TECHNICAL DATA

• Use: not aggressive gases of the 3 families (dry gases)

• Threaded connections Rp (brass body): (DN 15 ÷ DN 25) according to EN 10226

• Threaded connections Rp: (DN 20 ÷ DN 50) according to EN 10226

• Flanged connections PN 16: (DN 32 ÷ DN 300) according to ISO 7005

• On request ANSI 150 flanged connections

• Power supply voltage: 12 Vdc, 12 V/50 Hz, 24 Vdc, 24 V/50 Hz, 110 V/50 Hz, 230 V/50-60 Hz

• Power supply voltage tolerance: -15% ... +10%

• Max. working pressure: 500 mbar or 6 bar

• Environment temperature: -20 ÷ +60 °C

• Max superficial temperature: 80 °C

• Protection degree: IP65

• Class (DN 15 ÷ DN 200):A

• Class (DN 300): B

• Group: 2

• Closing time: <1 s

COILS: poliammidic resin encapsulated with glass fibre, connection type DIN 43650; the insulation class is F (155°) and the enamelled copper wire class is H (180°).

MATERIALS

• Die-cast aluminium (UNI EN 1706)

• OT-58 brass (UNI EN 12164)

• 11S aluminium (UNI 9002-5)

• Galvanized steel, 430 F stainless steel and 303 (UNI EN 10088)

• NBR rubber and Viton (UNI 7702)

• Viledon

.jpg)

Component PDF's:

Solenoid Valve

Download Spec Sheet

Solenoid Valve1

Download Spec Sheet

Solenoid Valve2

Download Spec Sheet

Solenoid Valve3

Download Spec Sheet