Sandfirden Gas Engines & Gensets

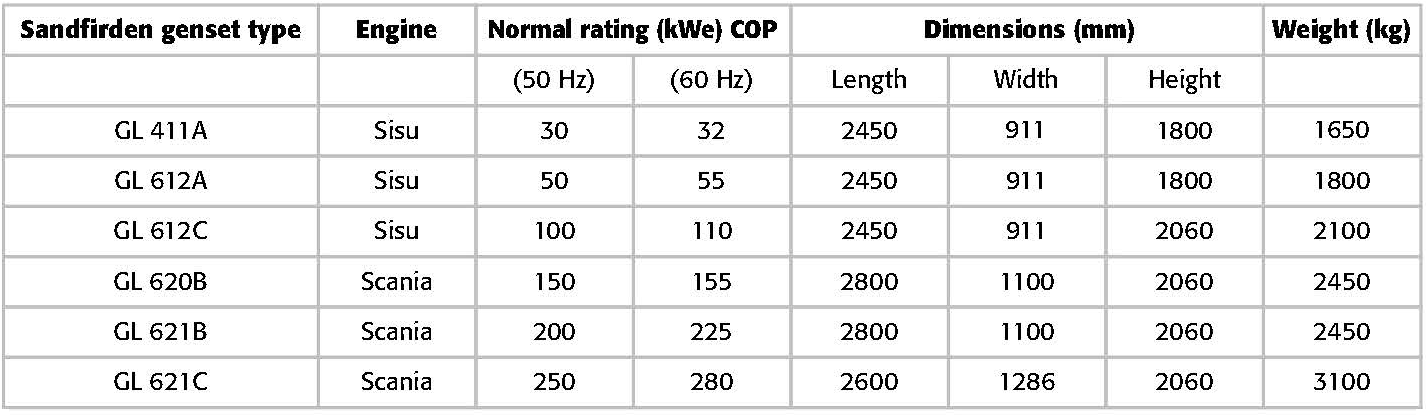

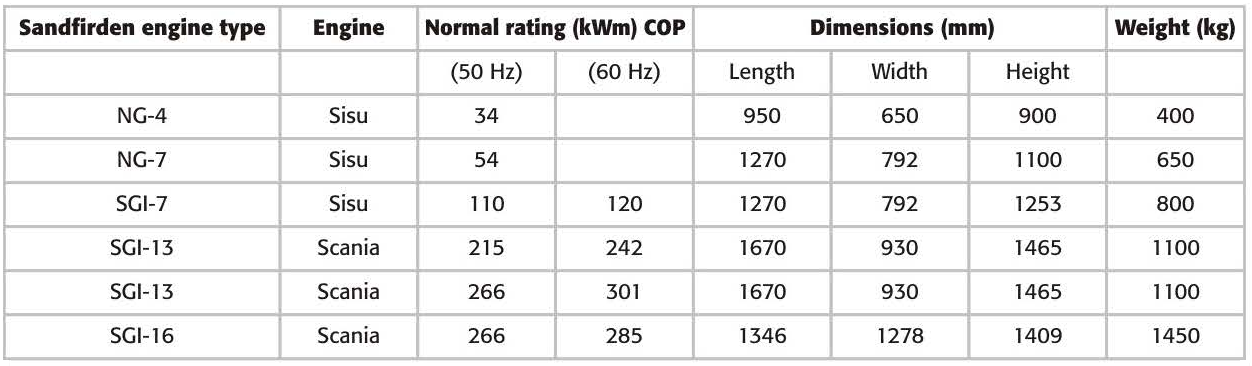

Sandfirden Technics supplies a range comprising both standard and custom-made engines and gensets. Their most important benefits are reliability, competitive prices and performance, plus the fact that standard versions can usually be supplied straight from stock. Even worldwide.The real skill lies in linking engine and generator. Knowledge, creativity and skill are needed to match the set fully to its application. That’s the strength of Sandfirden Technics. The program comprises standard sets and custom-made combinations with optional noise-dampening housings and/or radiator cooling.

With Gas (LNG) engines there is increasingly stricter emissions requirements and rising costs, it’s certainly worthwhile checking out the use of LNG as the main fuel. And that’s possible! Sandfirden Technics knows a lot about LNG. So we can also advise you about applications and the special safety measures that apply.

Engine Management System

The control box designed by Sandfirden Technics constantly checks, controls and protects the engine – guaranteeing top performance and reliability.For customers Remote Technology makes it possible to obtain quick and easy access to the unit. Data can be accessed by desktop computer, laptop or even by smartphone.

BIOGAS and natural gas as a sustainable fuel , which produces much lower emissions. It saves tons of CO2 and develops the greenest application whilst offering huge financial savings through reduced primary energy costs. The flexible mounted generator sets are efficient, reliable and available in various electrical loads with different options. Cogeneration or Combined Heat and Power (CHP) Technology converts gas into both electricity and heat. The recovery of heat from both the engine jacket cooling water and the exhaust gas flow make it possible for us to achieve an overall system efficiency in excess of 90%.

Design and lean-burn technology make the Sandfirden gas generator sets extremely clean and economical. The proven reliability allows the generator sets to be operated 24 hours a day, 7 days a week. Operating costs are low due to long maintenance intervals and low oil consumption.

Component PDF's:

Technical Quote - GL621-C

Download Spec Sheet

Technical Quote - GL621-B

Download Spec Sheet

Technical Quote - GL612-C

Download Spec Sheet

E0834

Download Spec Sheet